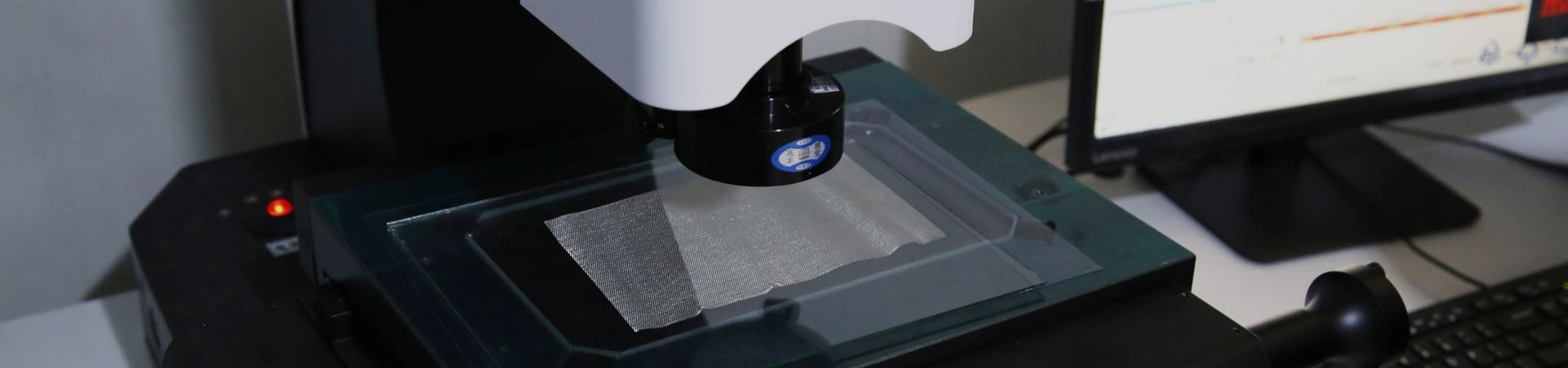

Understanding the Basics: What Is Stainless Steel Square Mesh?

Stainless steel square mesh, often referred to as square weave mesh or woven wire mesh, is one of the most versatile and widely used wire cloth types in industrial and commercial applications. As the name implies, its defining characteristic is its uniform square openings, formed by weaving straight, parallel warp and weft wires (also known as shute wires) over and under each other in a precise 90-degree pattern. This straightforward yet robust construction results in a stable, reliable, and consistent panel or roll product. You will commonly encounter it described as stainless steel square mesh panels when it is cut and finished for specific uses, or simply as a roll of stainless steel square wire mesh. Its primary functions include sizing, sorting, screening, and filtering a vast array of materials, from aggregates and chemicals to food products. Beyond filtration and separation, its structural integrity and clean appearance make it ideal for guarding, fencing, architectural facades, and machine components. When you source this product, understanding its fundamental composition—specifically the grade of stainless steel used—is the first critical step in ensuring it performs as expected in your specific environment. The two grades you will most frequently need to choose between are 304 and 316, and the correct selection hinges entirely on the conditions it will face.

The Core Difference: Material Composition of 304 vs. 316 Stainless Steel

The fundamental difference between 304 and 316 stainless steel square mesh lies in their alloy chemical composition, which directly dictates their performance. Both grades are part of the austenitic family of stainless steels, which gives them excellent formability and toughness. The base composition for both includes a high percentage of Chromium (approx. 18%) and Nickel (approx. 8-10%), which provide the fundamental corrosion resistance and "stainless" property by forming a protective, invisible passive layer of chromium oxide on the surface. The critical differentiator is the addition of Molybdenum (Mo) in grade 316. Typically comprising 2-3% of the alloy, Molybdenum significantly enhances the material's resistance to specific types of attack. This addition makes 316 a more advanced and specialized grade. When you examine a mill test certificate for your high quality square hole weaving wire mesh, you will see this compositional difference clearly outlined. For 304, the maximum carbon content is also a consideration (hence the variant 304L for welding applications to prevent carbide precipitation), but the absence of Molybdenum remains the key factor. Understanding this elemental difference is crucial because it translates directly into performance, longevity, and ultimately, the total cost of ownership for your project, even if the initial purchase price of 316 is higher.

Performance Showdown: Corrosion Resistance in Different Environments

The divergence in material composition leads to a significant performance gap, particularly in corrosion resistance, which is the primary reason for selecting stainless steel in the first place. This is not a matter of one grade being universally "better" than the other, but rather one being more suitable for your specific operational environment.

304 Stainless Steel Square Mesh: The All-Rounder for Most Applications

Grade 304 stainless steel square mesh offers excellent corrosion resistance for a wide spectrum of applications. It effectively resists oxidation, withstands exposure to most common organic chemicals, and performs reliably in mild atmospheric and freshwater environments. This makes it an incredibly cost-effective solution for the majority of industrial and architectural uses. However, its primary weakness is its susceptibility to chlorides, such as those found in saltwater or de-icing salts. In these environments, 304 is prone to pitting and crevice corrosion—localized attacks that can penetrate the protective oxide layer and lead to premature failure. Therefore, while 304 is the industry standard workhorse, you must ensure your application is free from persistent chloride exposure or other highly corrosive agents.

316 Stainless Steel Square Mesh: The Champion for Harsh Conditions

The addition of Molybdenum in 316 stainless steel square mesh dramatically elevates its defense against chemical attack. This grade exhibits superior resistance to pitting and crevice corrosion caused by chlorides and acidic environments. It is the unequivocal choice for applications involving saltwater, brine, chemical processing solvents, and plant fertilizers. The Molybdenum alloy strengthens the passive layer on the steel's surface, making it more stable and resilient. When your stainless steel square mesh panels are destined for marine applications, coastal architectural features, pharmaceutical processing, or any setting with exposure to aggressive industrial chemicals, specifying 316 is not just recommended; it is essential for ensuring structural integrity and long-term performance. The investment in 316 upfront prevents costly downtime, replacements, and project failures down the line.

Strength and Durability: Mechanical Properties Comparison

While corrosion resistance is the paramount differentiator, you may also consider the mechanical properties of these two grades. In terms of tensile strength and yield strength, 316 stainless steel generally offers marginally higher values than 304 due to its alloy content. However, for virtually all applications involving stainless steel square wire mesh used in screening, filtering, or partitioning, this difference in mechanical strength is negligible and rarely the deciding factor. Both grades provide more than sufficient durability and structural stability for their intended uses. The weave pattern, wire diameter, and mesh opening are far more significant determinants of the panel's strength and rigidity. The true measure of durability in this context is not load-bearing capacity but longevity in a given environment. A 304 stainless steel square mesh in a dry, indoor setting will last for decades, while the same panel could fail quickly in a coastal environment where 316 stainless steel square mesh would thrive. Thus, your focus should remain on the environmental corrosion factors rather than pure mechanical specs.

Making the Right Choice: Application-Based Recommendations

Translating the technical specifications into real-world scenarios is key to making the correct decision. Here is a practical breakdown of where each grade is most appropriately specified.

Ideal Applications for 304 Stainless Steel Square Mesh Panels

Industrial Screening and Sizing: Sorting aggregates, minerals, and materials in quarries and mining operations where corrosive chemicals are not present.

Food and Beverage Processing: Equipment for washing, sorting, and draining in food processing plants. 304 is often sufficient and is compliant with food-grade standards in many applications.

Architectural and Interior Design: Decorative mesh panels, balustrade infill, room dividers, and signage in indoor or sheltered outdoor environments.

Agricultural and Farming: Sieves, screens, and partitions in grain processing, animal fencing, and farming equipment.

Ventilation and Airflow: Guards for machinery, fan covers, and ventilation screens in non-corrosive environments.

General Industrial Use: Safety guarding, machine partitions, and shelf infills in warehouses and factories.

Where You Must Specify 316 Stainless Steel Square Wire Mesh

Marine and Coastal Applications: Boat rails, security screens on coastal properties, sea water intake filters, and aquaculture cage netting.

Chemical and Pharmaceutical Processing: Equipment and machinery for processing aggressive chemicals, solvents, acids, and pharmaceuticals where high purity and corrosion resistance are mandatory.

Water and Wastewater Treatment: Filters and screens in desalination plants, wastewater treatment facilities, and other processing plants involving brackish or salt water.

Pollution Control: Scrubbers and filtration systems in industrial exhaust stacks that handle corrosive fumes.

Oil and Gas Industry: Filters and screens for upstream and downstream applications exposed to sour gas (H2S) and saline environments.

Medical Devices: Components for medical equipment that require repeated sterilization and high corrosion resistance.

Beyond Grade: Key Specifications for Your Stainless Steel Square Mesh Order

Selecting the right stainless steel grade is only part of the process. To ensure you receive the exact product for your needs, you must specify several other critical parameters for your square weave mesh:

Mesh Count (Openings per Inch): The number of openings in a linear inch. A higher mesh count indicates smaller openings.

Wire Diameter: The thickness of the individual wires used in the weave. A larger diameter creates a stronger, more durable mesh but reduces the open area.

Aperture Size (Micron or mm): The precise size of the open square, which determines the size of particles it can filter or separate.

Open Area (%): The percentage of the total surface area that is open space, crucial for calculating flow rates and filtration efficiency.

Width and Length: Whether you need rolls (standard widths like 1m, 1.2m, 1.5m) or pre-cut stainless steel square mesh panels to specific dimensions.

Edge Preparation: For panels, you may need finished edges (welded, hemmed, or folded) for safety and ease of installation.

Why Source Your Square Weave Mesh from Dashang?

At Dashang, we specialize in manufacturing high quality square hole weaving wire mesh in both 304 and 316 grades to meet your precise specifications. Our expertise ensures that you receive a product that performs as expected. We use premium raw materials and employ stringent quality control throughout the manufacturing process to guarantee consistent weave accuracy, material integrity, and performance. We offer a vast inventory of standard specifications and excel at providing custom solutions—whether you need unique panel sizes, specific wire diameters, or finished edges. Our technical team can help you analyze your application environment and make the most cost-effective material recommendation, ensuring you never overpay for performance you don't need or underestimate the requirements of a harsh environment.

Your Next Step: Requesting a Quote and Technical Support

Choosing the correct stainless steel square mesh is a critical decision that impacts the success and cost-efficiency of your project. To receive a detailed quotation and expert technical guidance, please provide us with the following information:

Intended Application: Describe what you will use the mesh for and the environment it will operate in.

Material Grade: Specify your preferred grade (304 or 316) based on the conditions, or ask for our recommendation.

Specifications: Provide the mesh count, wire diameter, and required dimensions (width x length for rolls, or length x width for panels).

Quantity: The total number of panels or meters required.

Contact us today with your requirements. Our specialists are ready to provide you with a competitive quote and ensure you get the exact stainless steel square wire mesh that delivers optimal performance and value for your specific project.