-

Mob.:+86 186 3280 7688

-

E-mali: sales@dswirecloth.com

Mob.:+86 186 3280 7688

E-mali: sales@dswirecloth.com

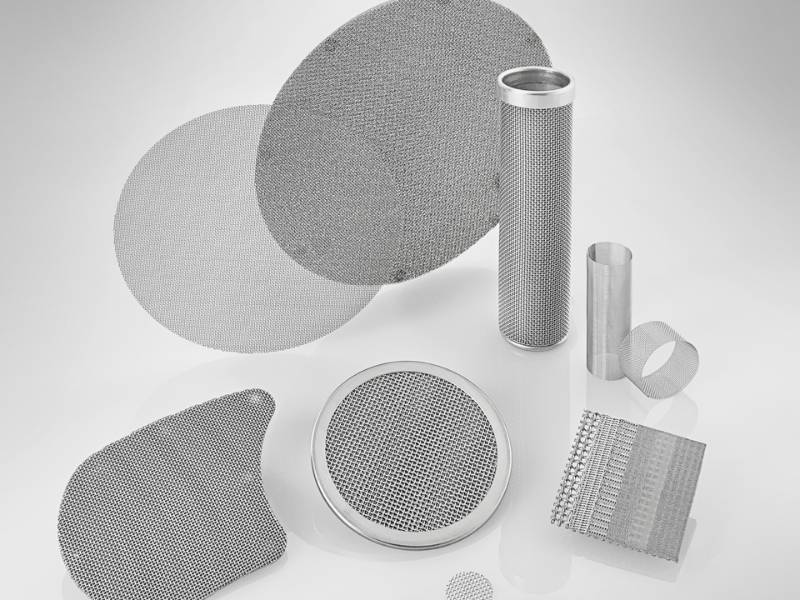

Dashang is a leading extruder screens & packs manufacturer in China, we can produce extruder screens to your specifications, using woven wire mesh as the filter media. These are generally of welded. These screens can be in the form of single layer disc screen, multi-layer screen packs of spot-welded or aluminum bound frame packs, multi-layer cylinder filter tubes, and special shaped.

Dashang Wire Mesh has available extruder screens at a reasonable price. In addition to maintaining a large inventory of extruder screens in various sizes, shapes, meshes, and materials for immediate shipment, we also produce high-quality customized extruder screens in our own factory that meet precise specifications to ensure consistent fit and performance.

PRODUCT DESCRIPTION

Extruder screen is a woven mesh filtration system that are welded and folded in specific shapes and sizes. The extruder screen has two configurations: single-layer and multi-layer, which can remove impurities from molten plastics. And the layer configuration of micron grading can be customized to be the materials filtration level. When choosing the specifications of the extruder screen, you need to consider factors such as pressure requirements, the characteristics of the materials used, and the required purification level. A mesh size that is too fine may achieve the required purification level, but it may cause damage to your device due to pressure levels. A large mesh size may allow for sufficient flow, but it can also allow pollutants to enter the final product.

Most extruder screens seen in the plastic industry are typically 20-150 mesh square mesh fabrics made of stainless steel to prevent corrosion/contact corrosion. In order to prevent product failure, plastic extrusion manufacturers must use sufficient filtering media during the plastic extrusion process. This is where the extruder screen comes into play. Using incorrect specifications can hinder the production speed of cleaning materials, as specifications can affect the temperature of the melt and the pressure in the system.

Wire mesh extruder screens provide distinct advantages compared to other filter media. Their durability and longevity allow them to endure the high temperatures and pressures typical in extrusion processes. These screens are also reusable after cleaning, offering a cost-efficient option for extended use. In the plastics and rubber processing industries, wire mesh extruder screens are a dependable and efficient method for filtering molten materials. They contribute to the quality and uniformity of the final product, helping to minimize defects and inconsistencies due to impurities and contaminants.

Dashang Wire Mesh could offer a variety of wire mesh screen with single layer including Dutch Woven mesh material made of carbon steel or stainless steel.

When should you use a single layer screen? Well, the answer is ultimately determined by the material and particles you’re filtering.For instance, if you are filtering a liquid with contaminant particles of variating sizes, you may benefit from using a multi-layer as the larger contaminants would potentially damage the mesh and significantly reduce its accuracy. On the other hand, you are filtering a liquid with minimal non-abrasive impurities or attempting to extract a filter cake, a single layer configuration may be suitable for you.

Generally it’s round in shape (we call wire mesh disc filter as well), usually composed of multiple layers of metal mesh with different mesh sizes (such as a combination of 20 mesh coarse mesh + 40 mesh fine mesh), with simple structure, easy installation and low cost. It's suitable for raw materials with low impurity content or ordinary extrusion processes with low requirements for filtration accuracy, commonly used in the production of conventional products such as PVC pipes and profiles.

The simple layer extruder screen has advantages of low cost, easy to replace, and suitable for most standard extruder filter plates. But small filtration area, easy to clog, and requires frequent replacement.

We have the ability to create any mesh pack and weld them in sequence to create strength and consistency in your filtration process. We also call it Welded Circular filter with Multiple Layers of Woven Mesh. Compared with single-layer filter round mesh, stainless steel multi-layer filter mesh has become a key component to ensure melt purity and stable equipment operation through layered filtration and extended filter life. Its specific functions are as follows:

1. Layered filtration to improve melt cleanliness

- Outer layer coarse filtration (such as 20-40 mesh): intercept unmelted raw material particles, carbides or mechanical impurities (such as metal debris) to protect the subsequent precision filtration layer.

- Middle layer transition (such as 60-100 mesh): capture smaller impurities (such as fibers, coking products) to prevent clogging of downstream molds.

- Inner layer fine filtration (such as 120-200 mesh): remove tiny suspended matter (such as undispersed pigments, gel particles) to ensure that the final product surface is smooth and defect-free.

2. Extend filter life and reduce downtime

- Layer-by-layer interception: disperse impurity load, avoid rapid clogging of a single layer, and extend the replacement cycle (2-3 times longer than the life of a single-layer mesh).

- Removable design: multi-layer mesh can replace damaged layers separately to reduce maintenance costs.

3. Optimize melt fluidity

- Uniform pore size distribution: Reduce turbulence when the melt passes through, maintain stable pressure, and avoid uneven thickness or surface defects caused by extrusion fluctuations.

Framed Packs have a seamless frame of dead-soft aluminum surrounding the screens. This provides for a better seal at the edge of the breaker plate. Frames can be customized to your exact requriements. Compared with multi-layer spot-welded filter disc, aluminum plate or stainless steel plate edge-wrapped filter has strong edge protection. The edge-wrapped frame protects the edge of the mesh to prevent curling or deformation, which is suitable for working conditions with particle scouring (such as sewage treatment); the screen packs supports more layers (such as 5-10 layers) and maintains overall stability through the edge-wrapped frame; the edge and mesh are made of the same material (such as 304/316L), and there is no risk of corrosion due to weld differences; in mass production, the automated folding process can reduce processing costs.

However, the pressure resistance of the edge-wrapped technology is weak, and overall deformation may occur under high pressure.

Dashang Wire mesh makes cylinder screen pack elements to-order, with welded seams and ends or seam welds only, in a range of diameters and lengths. We can provide a variety of mesh types to meet your process requirements. We manufacture screens for the plastic film industry.

Multi-layer Cylinder Filter Tubes has the following features:

- It is composed of multiple concentric cylindrical filter screens nested, and the mesh size of each layer increases step by step (such as outer layer coarse filtration, inner layer fine filtration).

- Combined with graded filtration and deep filtration, impurities are more evenly distributed.

The Cylinder Filter Tube has strong anti-clogging ability, extended continuous operation time; strong adaptability. But generally it has Large volume, and customized design required; The filter tubes als need time-consuming replacement and cleaning.

Dashang Wire mesh offers round, eliptical, rectangle, annular or rings, and other special shapes for customized.

Like Oval Extruder Screens. It has oval design, larger area than circular filter, can accommodate more impurities. Usually the oval filter adopts single-layer or multi-layer metal mesh composite structure.

The special extruder screens has the advantage of Increase the effective filtration area and extend the replacement cycle; as well reduce melt pressure fluctuations.

But the Installation requires a special screen plate, which has low compatibility; the initial cost is higher than the circular filter.

Continuous belt screens used with screen changers allows extruders to run continuously. We provide the quality screens to achieve peak productivity.

The belt-shaped metal mesh is combined with an automatic scraper system to remove surface impurities without stopping for replacement. There is no need to stop for screen replacement, extremely high production efficiency; the belt screen is suitable for high impurity loads.

However this kind of Screen Changer Belts has Complex equipment, huge initial investment and high maintenance technology requirements.

Extruder screens are a reliable and effective solution for filtering molten materials in the plastics and rubber processing industries.

Preventing product failures caused by pollutants during the plastic extrusion production process is the most common.When plastic extrusion manufacturers start production, raw or recycled materials are melted for filtration. In order to promote melt flow, the melt is subjected to tremendous pressure when passing through a medium containing multiple extruder screens, such as extruder crushing plates.When the melted plastic passes through the extruder screen, any contaminants that may cause product failure are removed, and the filtered plastic is transported to the rest of the production process.

Extruder screen size is very widely with each style, depending on the type of material and volume desire, it can be less than 1 inch in diameter or exceed 16 inches in diameter. Likewise, knish, shaved screens typically range in size from 2 to 5 to 3 inches to a larger 3.5~6.5 inches.

The Quality of the stainless steel wire must conform to the technical requirements and testing of the standard ASTM A580, and the quality of the stainless steel wire mesh must conform to the technical requirements and testing of the standard ISO9044 and ASTM E2016.The discs and packs’ surface is flat, clean, and the weft wires are tightly arranged without gaps, any mechanical damage, creases, or rust spots.

Dashang Wire Mesh provides customized services based on customer needs, including extruder screen mesh and cylindrical filter with different filtration accuracies, to meet different production environments and requirements. Please contact us! sales@dswirecloth.com

Request a quote

If you have any questions or want to buy our products please contact us at any time, we will reply you as soon as possible!

Tags:

Related Products