-

Mob.:+86 186 3280 7688

-

E-mali: sales@dswirecloth.com

Mob.:+86 186 3280 7688

E-mali: sales@dswirecloth.com

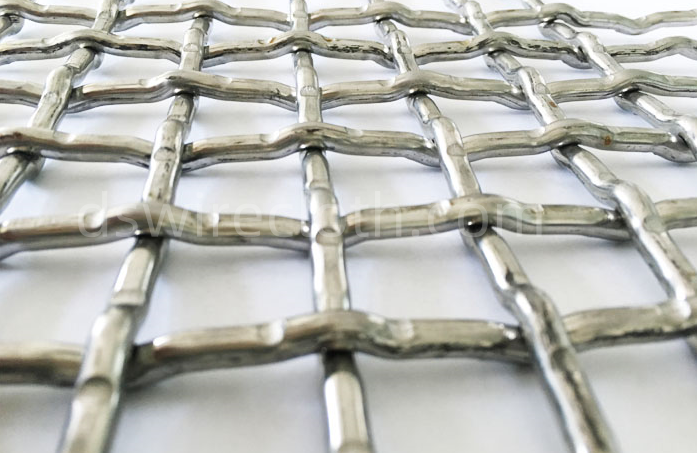

Dashang Wire Mesh produces and sells metal stainless steel pre-crimped wire mesh. Stainless steel crimped mesh is produced using wires that are pre-crimped before being woven on a loom.

By forming the crimps in advance, the mesh gains greater structural stability and uniform spacing, especially for meshes with larger openings. Over time, multiple crimping patterns have been created to enhance manufacturing efficiency, improve performance, and offer different visual styles.

PRODUCT DESCRIPTION

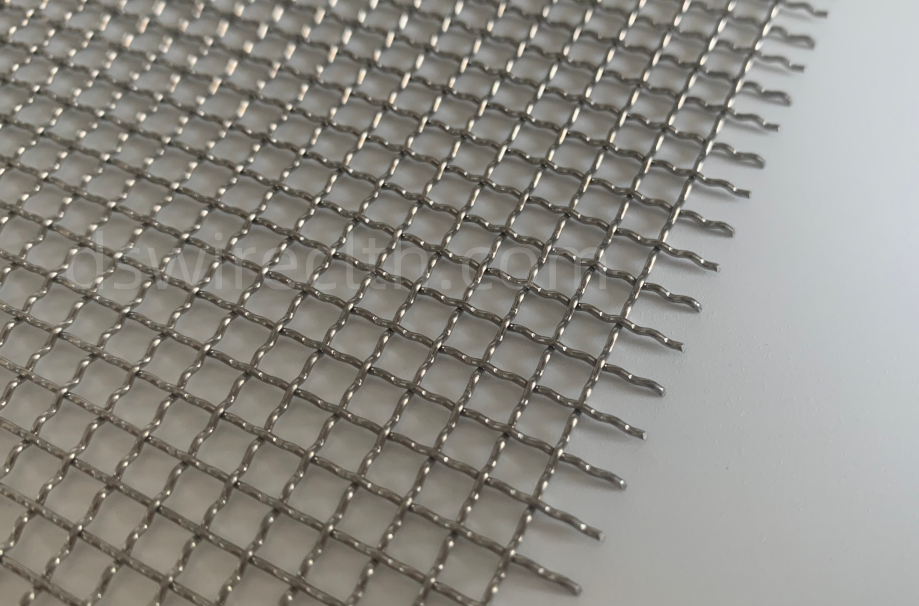

Stainless steel pre-crimped wire mesh with opening size from 0.70 mm to 50mm. It can be used for windows, partitions, roasting of meat and flour sieving or mine screens.

Compared with other plain weave or electric welding structures, crimped weave has unique performance advantages.

First, the corrugated interlocking structure allows the warp and weft wires to be tightly buckled, has strong anti-displacement ability, and the mesh remains stable for a long time;

Then the crimping weaving is a non-weld point weaving , which avoids the risk of weld cracking, and the metal mesh has high overall strength and long service life;

In addition, the crimped woven mesh has a high open porosity, and the effective filtration and screening area is usually 70-90%;

The crimped woven mesh also supports flexible customization, and the wire diameter and hole size can be adjusted according to customer requirements.

What metal wires can be used for crimping? Generally speaking, the choice of materials depends on the usage scenario. We will choose the best solution for customers based on the material properties and application scenarios. The following are common materials, properties and matching application scenarios:

Material | characteristic | Application Scenario |

Stainless steel | Corrosion-resistant, high temperature-resistant, hygienic and non-toxic | Food and pharmaceuticals, chemical filtration, marine engineering |

Mild steel + galvanized | Low cost, average rust resistance | Building fences, mining screens, agricultural equipment |

Brass/Copper | Electrical and thermal conductivity, strong decorative effect | Electromagnetic shielding, architectural decoration, artwork |

Aluminum Alloy | Lightweight and weather-resistant | Ventilation and heat dissipation net, curtain wall decoration |

Stainless Steel Crimped Wire Mesh

Stainless Steel Crimped Wire Mesh Crimped Decorative Mesh Stainless Steel Crimped Wire Mesh

Among them, stainless steel pre-crimped wire mesh is the most widely produced and sold metal crimped mesh. Especially in the field of industrial screening, stainless steel pre-crimped mesh is corrosion-resistant, wear-resistant, has a long life, and is not easy to damage , which greatly reduces the replacement frequency and maintenance workload. The comprehensive performance of stainless steel material enables stainless steel crimped mesh to adapt to a variety of harsh working conditions , especially suitable for screening, filtering, grading, protection and other applications under heavy loads, strong vibrations, large impacts, high precision requirements and corrosive environments. Although the initial cost may be higher than other metal woven meshes, the excellent durability and low maintenance cost of stainless steel crimped mesh often bring higher economic benefits in long-term operation.

Grinding weaving can also show different patterns. The following are the four most common weaving methods: Dashang Wire Mesh can recommend the most suitable weaving type to you according to customer needs and actual application areas.

Intermesiate Crimp Flat Top Weava Double Crimp Wesva Lock Crimp Weave

Metal crimped wire mesh is widely used in many industrial fields due to its unique weaving structure and superior performance.

1. Industrial screening and filtration

- Mining and quarrying: used for grading and screening various ores, crushed stone, gravel, coal, etc. Its high load-bearing capacity and impact resistance are very suitable for the working conditions of heavy loads, bulk materials and high-frequency vibrations in mines.

- Chemical/Pharmaceutical: Screening and grading of chemical raw materials such as fertilizers, plastic particles, resins, pigments, catalysts, etc .; grading and screening of powders and granules in the pharmaceutical industry (using 316L material) ; support nets for filtering corrosive liquids or gases.

- Food processing: flour screening, grain cleaning, screening of food raw materials such as starch, powdered sugar, salt, etc. (must meet food grade material requirements, such as 304/316).

-Dryer and cooler mesh belts (with both load-bearing and ventilation functions).

2. Environmental protection and energy

- Wastewater treatment: screen filter to intercept solid debris.

- Waste sorting: RDF (Refuse Derived Fuel) vibratory screening.

- Energy industry: coal screens in coal-fired power plants, screening of biomass energy (wood chips, straw pellets).

3. Architecture and decoration

- Curtain wall decoration: Copper/aluminum crimped mesh is used for building facades (light-permeable and breathable + artistic feel).

- Safety protection: construction site fencing, machinery and equipment protection covers (high impact resistance).

4. Agriculture and breeding

- Feed screening: grading of pellet feed, anti-blocking hole design.

- Farming fence: livestock cages (galvanized steel mesh is economical and durable).

5. Special industrial use

- Electronic industry: electromagnetic shielding mesh (copper mesh).

- Automobile manufacturing: engine filter support mesh.

6. Metallurgical Industry:

-Screening of coke, sintered ore and pelletized ore.

-Classification of metal powders (iron powder, copper powder, aluminum powder, etc.).

-Filter screen for molten metal (special high temperature alloy required).

7. Other industrial fields:

-Screening of glass and ceramic raw materials.

-Grading of abrasives (grinding wheels, sandpaper).

-Sieving of powder coatings.

-Used as a protective net and ventilation and heat dissipation net for machinery and equipment (both strong and beautiful).

-Decorative purposes (special wire diameter and aperture, used for building facades, interior partitions, etc., combining functionality and aesthetics).

With its corrugated interlocking structure, metal pre-crimped wire mesh has overturned traditional metal mesh in terms of stability, durability and load-bearing capacity, becoming the first choice in the fields of mine screening, high-end filtration, heavy-duty protection, etc. Dashang Wire Mesh comprehensively considers the three core parameters of material corrosion resistance, wire diameter strength, and aperture accuracy according to the actual needs of customers, so as to match the ultimate needs of customers in different working conditions.

Specifications of Stainless Steel Crimped Wire Mesh

Specifications of Stainless Steel Crimped Wire Mesh

Stainless steel pre-crimped wire mesh with opening size from 0.70 mm to 50mm. The wire mesh was made according to the technical requirements ASTM E2016. The materials of the wires for mesh are conforming to the requirements ASTMA580.

Following is the common specifications of stainless steel pre-crimped wire mesh:

| Mesh | Opening Size | Wire Diameter | Open Area | Roll Width Max | ||

| inch | mm | inch | mm | (%) | mm | |

| 2" | 1.884 | 47.86 | 0.116 | 2.94 | 88.76 | 2000 |

| 2" | 1.865 | 47.38 | 0.135 | 3.42 | 86.99 | 2000 |

| 2" | 1.841 | 46.76 | 0.159 | 4.04 | 84.73 | 2000 |

| 2" | 1.788 | 45.42 | 0.212 | 5.38 | 79.94 | 2000 |

| 1 1/2" | 1.396 | 35.46 | 0.104 | 2.64 | 86.62 | 2000 |

| 1 1/2" | 1.365 | 34.68 | 0.135 | 3.42 | 82.85 | 2000 |

| 1 1/2" | 1.341 | 34.06 | 0.159 | 4.04 | 79.92 | 2000 |

| 1×1 | 0.92 | 23.37 | 0.08 | 2.03 | 84.65 | 2000 |

| 1×1 | 0.884 | 22.46 | 0.116 | 2.94 | 78.19 | 2000 |

| 1×1 | 0.865 | 21.98 | 0.135 | 3.42 | 74.88 | 2000 |

| 2×2 | 0.453 | 11.51 | 0.047 | 1.19 | 82.14 | 2000 |

| 2×2 | 0.428 | 10.87 | 0.072 | 1.83 | 73.26 | 2000 |

| 2×2 | 0.396 | 10.06 | 0.104 | 2.64 | 62.75 | 2000 |

| 2×2 | 0.38 | 9.65 | 0.12 | 3.05 | 57.74 | 2000 |

| 3×3 | 0.279 | 7.1 | 0.054 | 1.37 | 70.26 | 2000 |

| 3×3 | 0.261 | 6.64 | 0.072 | 1.83 | 61.44 | 2000 |

| 3×3 | 0.253 | 6.44 | 0.08 | 2.03 | 57.8 | 2000 |

| 4×4 | 0.222 | 5.64 | 0.028 | 0.71 | 78.89 | 2000 |

| 4×4 | 0.203 | 5.16 | 0.047 | 1.19 | 66.03 | 2000 |

| 4×4 | 0.187 | 4.75 | 0.063 | 1.6 | 55.96 | 2000 |

| 4×4 | 0.17 | 4.32 | 0.08 | 2.03 | 46.28 | 2000 |

| 5×5 | 0.165 | 4.19 | 0.035 | 0.89 | 68.03 | 2000 |

| 5×5 | 0.153 | 3.89 | 0.047 | 1.19 | 58.64 | 2000 |

| 5×5 | 0.137 | 3.48 | 0.063 | 1.6 | 46.93 | 2000 |

| 6×6 | 0.132 | 3.34 | 0.035 | 0.89 | 62.37 | 2000 |

| 6×6 | 0.126 | 3.19 | 0.041 | 1.04 | 56.9 | 2000 |

| 6×6 | 0.12 | 3.04 | 0.047 | 1.19 | 51.68 | 2000 |

| 6×6 | 0.104 | 2.63 | 0.063 | 1.6 | 38.69 | 2000 |

| 8×8 | 0.108 | 2.75 | 0.017 | 0.43 | 74.75 | 2000 |

| 8×8 | 0.097 | 2.47 | 0.028 | 0.71 | 60.28 | 2000 |

| 8×8 | 0.09 | 2.29 | 0.035 | 0.89 | 51.79 | 2000 |

| 8×8 | 0.078 | 1.99 | 0.047 | 1.19 | 39.09 | 2000 |

| 10×10 | 0.083 | 2.11 | 0.017 | 0.43 | 69.01 | 2000 |

| 10×10 | 0.075 | 1.91 | 0.025 | 0.635 | 56.25 | 2000 |

| 10×10 | 0.068 | 1.73 | 0.032 | 0.813 | 46.23 | 2000 |

| 10×10 | 0.053 | 1.35 | 0.047 | 1.19 | 28.25 | 2000 |

| 12×12 | 0.066 | 1.69 | 0.017 | 0.43 | 63.5 | 2000 |

| 12×12 | 0.06 | 1.54 | 0.023 | 0.58 | 52.71 | 2000 |

| 12×12 | 0.055 | 1.41 | 0.028 | 0.71 | 44.16 | 2000 |

| 12×12 | 0.048 | 1.23 | 0.035 | 0.89 | 33.59 | 2000 |

| 14×14 | 0.056 | 1.43 | 0.015 | 0.38 | 62.5 | 2000 |

| 14×14 | 0.052 | 1.31 | 0.02 | 0.5 | 52.48 | 2000 |

| 14×14 | 0.043 | 1.1 | 0.028 | 0.71 | 37.05 | 2000 |

| 16×16 | 0.048 | 1.21 | 0.015 | 0.38 | 57.86 | 2000 |

| 16×16 | 0.045 | 1.14 | 0.018 | 0.45 | 51.34 | 2000 |

| 16×16 | 0.04 | 1.01 | 0.023 | 0.58 | 40.28 | 2000 |

| 16×16 | 0.035 | 0.88 | 0.028 | 0.71 | 30.55 | 2000 |

| 18×18 | 0.042 | 1.06 | 0.014 | 0.35 | 56.55 | 2000 |

| 18×18 | 0.039 | 0.98 | 0.017 | 0.43 | 48.34 | 2000 |

| 18×18 | 0.036 | 0.91 | 0.02 | 0.5 | 41.69 | 2000 |

| 18×18 | 0.033 | 0.83 | 0.023 | 0.58 | 34.69 | 2000 |

| 20×20 | 0.036 | 0.92 | 0.014 | 0.35 | 52.48 | 2000 |

| 20×20 | 0.033 | 0.84 | 0.017 | 0.43 | 43.75 | 2000 |

| 20×20 | 0.03 | 0.77 | 0.02 | 0.5 | 36.76 | 2000 |

| 20×20 | 0.027 | 0.69 | 0.023 | 0.58 | 29.52 | 2000 |

Production and Inspection Standards:

The Quality of the stainless steel wire must conform to the technical requirements and testing of the standard ASTM A580, and the quality of the stainless steel filter mesh must conform to the technical requirements and testing of the standard ASTM E2016. For more information, please consult us sales@dswirecloth.com about the quality control system and inspection standard description

Packing:

All overall wire mesh are packed with waterproof paper and polyethylene film, and then put into a fumigation-free wooden plate. Packaging methods should take into account the possibility of wire mesh corrosion or mechanical damage. Any special packaging should be noted and agreed by the seller. For more information please consult us sales@dswirecloth.com on packaging systems

Ordering information:

√ The quantity required;

√ Aperture width;

√ Wire diameter;

√ Material;

√ Type of weave;

√ The overall size including special quality requirement.

Request a quote

If you have any questions or want to buy our products please contact us at any time, we will reply you as soon as possible!

Related Products